The energy consumption and environmental performance of the feeders vary according to the specific model, application scenario and method. The following is a detailed analysis of the energy consumption and environmental performance of the feeders:

I. Energy consumption

Reciprocating compressor

Energy consumption factors: The energy consumption of reciprocating compressors is affected by a variety of factors, including gas characteristics, production and operation parameters, thermal conductivity, etc.

Gas characteristics: such as gas specific gravity, adiabatic coefficient, etc., these properties will affect the energy consumption of the compressor.

Production and operation parameters: such as intake air temperature, intake and exhaust pressure, etc., changes in these parameters will affect the exhaust volume and power of the compressor, thus affecting the energy consumption.

Thermal conductivity: the greater the thermal conductivity, the better the heating coefficient of the gas, but the exhaust volume will decrease, and there is a difference between the compression coefficient, which will also affect the energy consumption.

Energy saving measures:

Optimize compressor cooler performance to improve cooling efficiency.

Reduce the compressor cylinder temperature by controlling the temperature and optimizing the structure to achieve consumption reduction.

Ensure the quality of the gas and avoid impurities such as water or dust in the gas that will increase energy consumption.

Adjust the compressor cylinder clearance in time to achieve the goal of energy saving and consumption reduction.

Strengthen the compressor maintenance quality, replace the worn parts in time, and maintain the compressor performance.

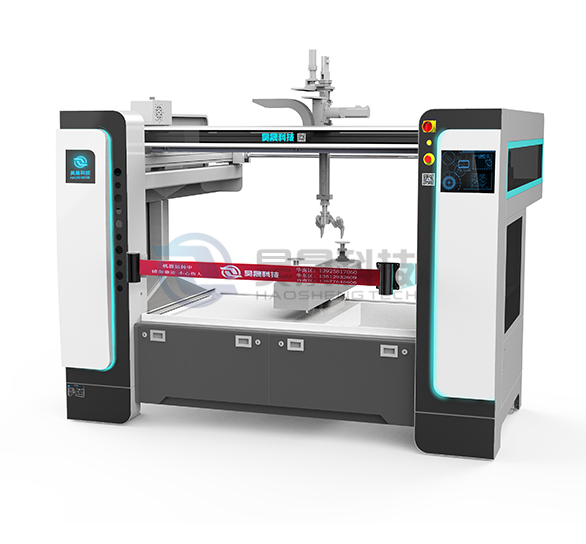

Five axis reloader

Motor application: The five-axis repeater is mostly driven by motors with higher energy efficiency ratio such as servo motors, which can convert more electrical energy into mechanical energy during operation, which can effectively reduce energy consumption compared with traditional motor drive methods.

Intelligent control system energy saving: its intelligent control system can automatically adjust the operating parameters of the equipment according to the actual work situation, such as in the workpiece spraying gap or equipment standby state, automatically reduce the speed or suspend some unnecessary actions, so as to reduce energy waste and improve energy efficiency.

Second, environmental performance

Reciprocating compressor

Environmental benefits: Reciprocating compressors are less powerful and require relatively less energy than other types of compressors, such as rotary compressors. In addition, the reciprocating motion can reduce the oxidation and flow speed of the liquid compared to the rotating motion, and reduce the production of pollutants.

Environmental protection measures: By optimizing the compressor structure, improving cooling efficiency, reducing cylinder temperature and other measures, not only can reduce energy consumption, but also reduce pollutant emissions, improve the environmental performance of the equipment.

Five axis reloader

Closed spraying environment: The five-axis repeater usually works in a relatively closed spray room, equipped with an effective ventilation system and paint mist filter device, such as in the design of the water curtain environmental spray room, through the adsorption of the water curtain, most of the solid particles in the paint mist can be captured, reducing the pollution of the paint mist emission to the environment.

Optimized atomization: The spray gun of the five-axis repeater adopts atomization technology, which can atomize the paint into smaller and uniform particles, so that the coating is better attached to the surface of the workpiece, while reducing the production of paint fog, and further reduce the pollution to the environment.