In the automobile manufacturing industry, the five-axis repeater (or five-axis machining) has a wide range of applications, mainly reflected in the following aspects:

1. Manufacturing of key components

Engine parts: The five-axis reloader can be used to process the cylinder block, cylinder head, crankshaft, connecting rod and other complex parts of the automobile engine. These parts are not only complex in shape, but also have extremely high requirements for accuracy and material properties, and the high precision and efficiency of the five-axis repeater can meet these requirements.

Suspension system: The automotive suspension system is a key component to ensure the smoothness and comfort of the car, and the five-axis retractor can process the key components with high precision to ensure their performance and quality.

2. Manufacture of body and frame

In automobile manufacturing, the manufacture of body and frame requires high precision and efficiency. The five-axis reloader can improve the production efficiency and quality of body and frame components through high-speed cutting and complex surface machining capabilities.

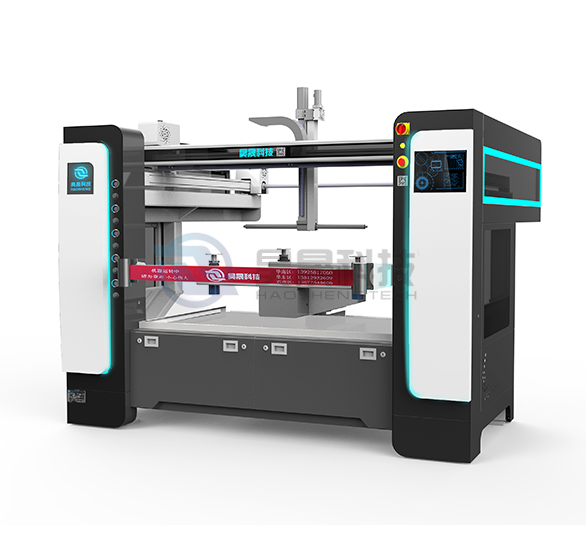

Five axis reloader

Third, the application of composite materials

With the development of automobile lightweight trend, the application of composite materials in automobile manufacturing is more and more extensive. The five-axis reloader can complete the engraving and milling of composite parts, such as body, frame, seat and other parts, improving production efficiency and production quality.

Four, mold manufacturing

In automobile manufacturing, mold manufacturing is an indispensable part. The five-axis resetter is also widely used in the mold manufacturing industry, and can be used to process a variety of complex injection molds, die-casting molds, etc., to meet the high precision and complex shape requirements of molds in automobile manufacturing.

V. Other applications

In addition to the above applications, the five-axis reloader can also be used in other areas of automotive manufacturing, such as the manufacture of automotive electronic equipment, automotive interior processing, etc. Through five-axis linkage machining, high-precision and efficient cutting and processing can be achieved, and the overall quality and efficiency of automobile manufacturing can be improved.

The key steps and points mainly include the following aspects: