The repeated positioning accuracy of the six-axis repeater will vary according to different brands, models, manufacturing processes, and components used. The repeated positioning accuracy of the common six-axis repeater on the market is between ±0.02mm and ±0.1mm.

For example, Epson's C4 series six-axis robot can maintain repeated positioning accuracy within ±0.02mm when performing the same task multiple times. In the Denso six-axis robot sold by Kunshan Dingsuda Automation Equipment Co., LTD., the repeated positioning accuracy of VS6556G is ±0.02mm, and the repeated positioning accuracy of VS6577G is ±0.03mm. In addition, some domestic six-axis repeater may repeat the positioning accuracy of about ±0.05mm or slightly higher. Of course, if the accuracy requirements are higher, by using better parts, advanced control systems and precision manufacturing processes, the repeated positioning accuracy of the six-axis repeater can reach a higher level, but the corresponding cost will also increase.

Some specially designed six-axis regenerators:

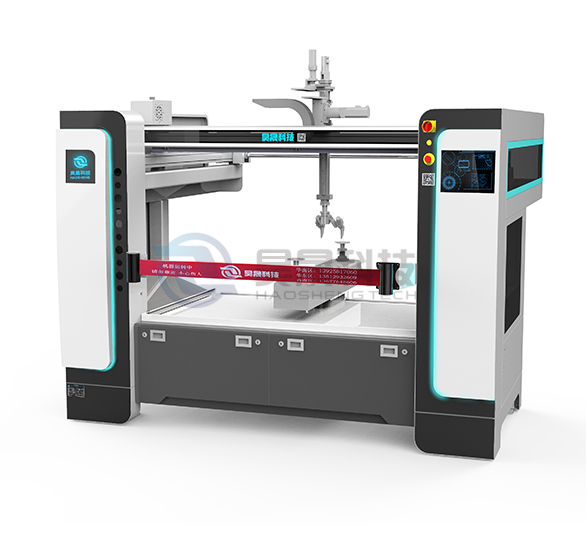

Six axis camber feeder:

Design features: This six-axis repeater is specially designed for the processing or spraying of camber workpieces. Its six-axis freedom of movement can be well adapted to the complex shape of the arc surface, so that the processing or spraying process is more uniform and accurate. For example, in the surface treatment of some curved plastic shells and metal curved parts, the six-axis camber retractor can flexibly adjust the Angle and position of the spray gun or processing tools to ensure that each part of the camber can be well treated.

Structural advantages: It is usually equipped with a special track and slider structure, so that the six-axis camber plate can move and rotate freely in multiple directions, which is convenient for the camber workpiece. In addition, some six-axis camber regenerators also use high-precision rotary drive motors and advanced control systems to further improve the accuracy and stability of camber processing or spraying.

Miniaturized six-axis repeater:

Application scenario targeted: mainly used in the limited space of the working environment, or for small pieces of fine occasions. For example, in the electronic equipment manufacturing industry, for the processing of small circuit boards, electronic components, etc., miniaturized six-axis replicators can flexibly operate in a small space and will not be limited by space.

Design improvements: The structural design will be more compact, and the size of the individual components will be optimized to reduce the overall volume of the equipment. At the same time, in order to ensure high motion accuracy and stability in the case of miniaturization, high-quality parts and advanced manufacturing processes are used.

High speed six-axis repeater:

High speed performance: The movement speed of this type of six-axis repeater is extremely fast, and it can complete a large number of work tasks in a short time. Key components such as motors and transmissions have been specially designed and optimized to meet the needs of high-speed motion. For example, in some large-scale production lines, high-speed six-axis repeater can quickly carry out the workpiece handling, assembly, spraying, etc., which greatly improves the production efficiency.

Accurate control: In order to ensure accuracy under high-speed movement, high-speed six-axis repeater is usually equipped with advanced control systems and high-precision sensors to monitor and adjust the motion state of the machine in real time to ensure that every action can be completed accurately.

Customizable six-axis reloader:

Meet individual needs: customized design according to the specific needs of different customers, whether in structure, function or control system, etc., can be adjusted and optimized according to customer requirements. For example, some customers may require a six-axis reloader with a special fixture or tool to better fix and shape the workpiece; Some customers may require the device to have a special communication interface so that it can seamlessly connect and work together with other devices.

Flexible design scheme: Manufacturers will conduct in-depth communication and understanding with customers, formulate detailed design schemes according to the specific needs of customers, and manufacture and assembly in strict accordance with the scheme during the production process to ensure that the equipment can meet customer expectations.

Six-axis repeater with vision system:

Visual auxiliary functions: Equipped with visual systems, such as cameras, image sensors, etc., can carry out real-time vision and recognition of the workpiece. Through the vision system, the six-axis repeater can accurately obtain the position, shape, color and other information of the workpiece, and then automatically adjust its movement trajectory and mode according to this information to achieve more accurate operations. For example, in the assembly process of auto parts, the six-axis retractor with a vision system can accurately identify different types of parts and assemble them correctly on the car.

Improve production quality and efficiency: The addition of the vision system not only improves the accuracy of the six-axis repeater, but also enables real-time monitoring of the production process, timely detection and correction of problems in production, thereby improving production quality and efficiency. At the same time, the vision system can also be integrated with the control system of the equipment to achieve automated production processes, reduce manual intervention, and reduce production costs.